According to the press service of the National Research Nuclear University MEPhI, its researchers have developed an efficient method of determining the tensile strength limit of reactor fuel pellets. The method is based on the Brazilian test and a new strength analysis formula.

The ultimate tensile strength is a basic quality indicator when nuclear fuel is produced from uranium dioxide powder. Generally, it is determined by testing samples dozens of times bigger than the fuel pellets, which are not more than 6-8 mm in length and diameter.

It is impossible to determine the maximum tensile strength using standard methods with such small samples. This is why the university proposed an unusual solution: to subject the pellets to the Brazilian test.

The “Brazilian test” involves testing a short cylinder, which is placed on its side for compression. This method has a long and successful record in testing rock specimens not less than 50 mm in diameter and 0.2-0.75 diameters thick. However, the method cannot be used when there is a hole in the centre of the specimen, which is the case with fuel pellets.

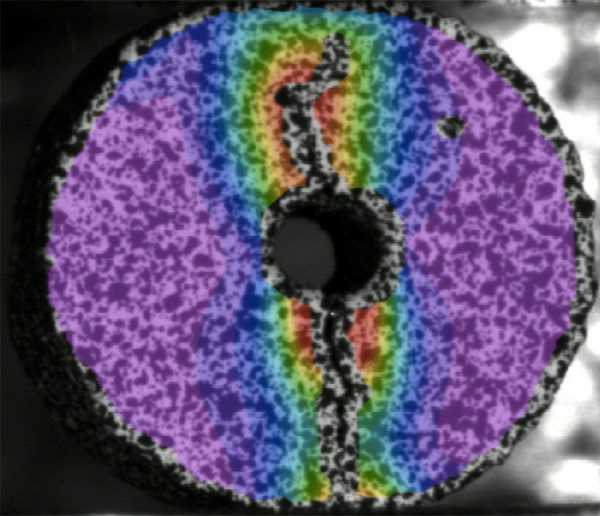

A coloured picture of the distribution of deformations at surface points of a cast iron specimen with a hole

“We have made a design analysis of the specimen’s stress-deformed state at various points, using the finite-element method in the ANSYS software package. It has shown how the distribution of tension over the cylinder base surface and over the section along the plane of symmetry and load depends on the hole,” said Vladimir Goltsev, an associate professor at the university’s Strength Physics Department.

He added that the results of the analysis were confirmed by experiments, using samples of model materials such as cast iron and graphite as well as nuclear fuel samples. In their experiments, researchers relied on the digital image correlation method in conjunction with the VIC installation from the United States, which makes it possible to analyze the movement and deformation of sample surface points in the course of loading.

“The research has led us to the conclusion that the Brazilian test can be used successfully to test small-sized samples of fragile materials and it has also made it possible for us to propose our formula for calculating nuclear fuel tensile strength,” Goltsev said.

These research results have been presented at the 16th International School-Conference “New Materials: Tolerant Nuclear Fuel” held at the University at the initiative of the ion-beam materials treatment school of the university’s Material Science Department.

Sourse: sputniknews.com