1. Introduction

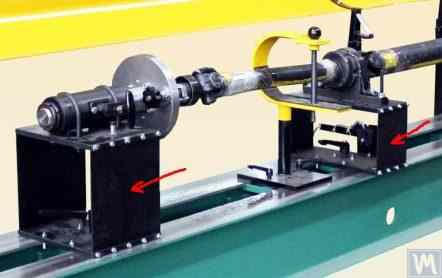

This article examines balancing machines, exploring their types, structural features, and operational principles.

2. Purpose and Application

A balancing machine is a technological device designed to correct static or dynamic imbalances in rotating components (rotors). Imbalances can lead to vibrations, increased wear, and equipment failure. Balancing machines are crucial in various sectors such as mechanical engineering, aviation, automotive industry, and energy production.

3. Types of Balancing Machines

There are two primary types of balancing machines:

Soft-bearings balancing Machines

- Feature flexible supports made from spring suspensions, spring-loaded carriages, or flat/cylindrical spring supports.

Soft-bearings balancing Machines: Have rigid supports crafted with figured slots or cuts.

4. Design Features

4.1 Soft-bearings balancing Machines

Advantages:

- Simple design

- Low cost

- High sensitivity to imbalance

- Effective for balancing light rotors (up to 200 kg)

Disadvantages:

- Limited load capacity

- Not suitable for balancing rotors at critical rotational frequencies

4.2 Hrad bearings balancing Machines

Advantages:

- Flexibility: Suitable for rotors of various sizes and weights

- Can balance at low rotational speeds

- High accuracy in balancing

Disadvantages:

- Complex design

- Higher cost

5. Choosing a Balancing Machine

The selection of a balancing machine depends on factors such as:

- Rotor type: weight, dimensions, bearing type

- Required balancing accuracy

- Productivity

- Budget

6. Recommendations for Selection

For balancing light rotors (up to 200 kg) within a limited budget, resonance machines are recommended. For balancing heavier and variously sized rotors, and for high-precision balancing, pre-resonance machines are advisable. When selecting a machine, it’s crucial to review user feedback and compare the specifications of different models.

7. Conclusion

Balancing machines are essential tools for ensuring the reliable and long-lasting operation of rotating components.

8. Additional Information

For more detailed guidance on DIY balancing machines, visit: https://vibromera.eu/diy-balancing-machines/

About Vibromera and Balanset

Vibromera is an established manufacturer based in the EU, known for its expertise in developing advanced balancing equipment for industrial machinery. Their products are essential for optimizing the performance of rotating components, helping to extend the lifespan of machinery and reduce the likelihood of premature breakdowns due to imbalance.

Their flagship product line, Balanset, offers portable balancing machines that are versatile and user-friendly. These machines allow technicians to perform precise on-site balancing of various rotating elements, which is crucial for sectors like automotive, aerospace, energy, and general manufacturing. Balanset machines are especially valued for their ability to deliver high-precision adjustments in environments where dismantling equipment would be impractical or costly.

Together, Vibromera and its Balanset range are dedicated to providing innovative solutions that promote reliability and efficiency in industrial operations around the world.